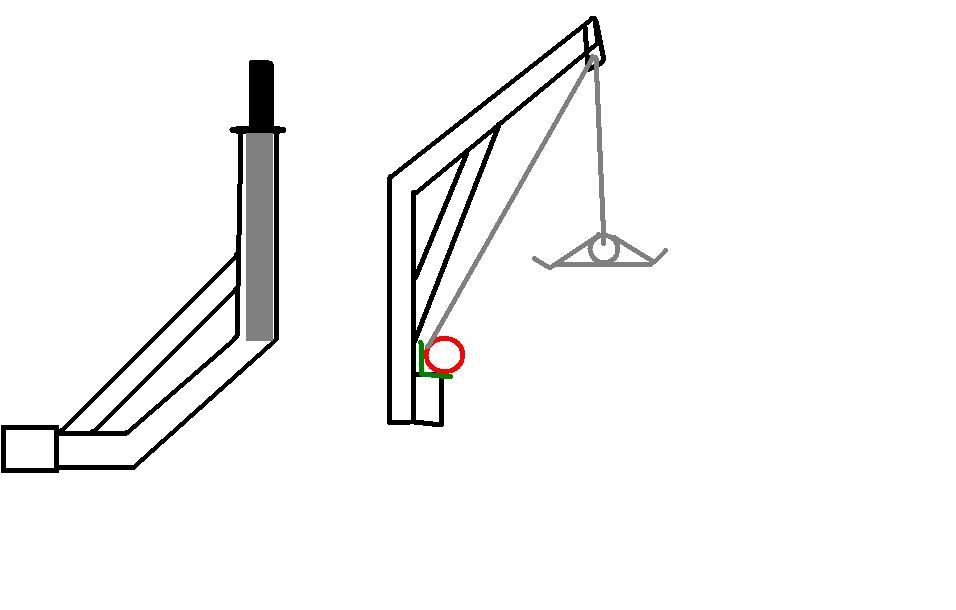

Totally original design....

Thanks for the ideas Dale, after some discussion on another site, while there might be some strength increase running to the ground a few new issues are created and they suggested welding a trailer jack to it if it squatted the truck too far before breaking.

Let's see em.

Let's see em.

Comment