What gauge metal is best?

Announcement

Collapse

No announcement yet.

School me on building a smoker

Collapse

X

-

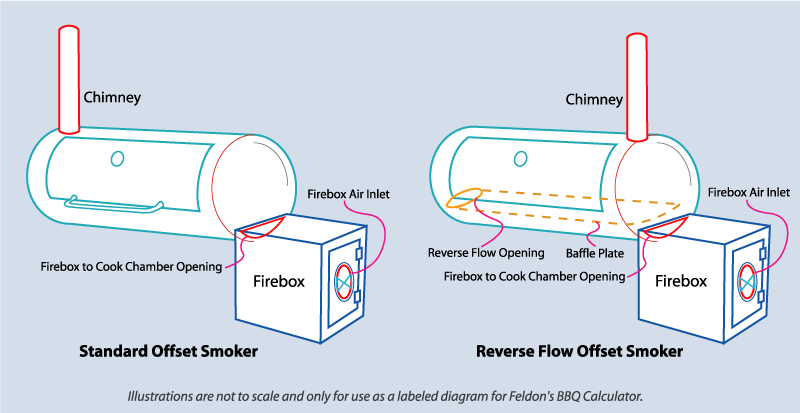

Originally posted by horns07 View PostWhat makes reverse flow better than convintual

Much more even temp across the whole cooking surface.

My trailer pit has a 30" x 6' cooking area, as a standard flow with every imaginable baffle it had a 35-50 degree temp variance from one area to another.

I modified it to reverse flow and now my temp variance is in the single digits anywhere on the pit.

Comment

-

There so many options and possibilities that it's an impossible question to answer.

As far as gauge, ur headed the wrong direction think quarters of an inch. I would not build one less than 1/4. Baffle between firebox and smoke box is completely necessary. Heat distribution plates however are. You will always have heat variance without them. If you don't do reverse flow. 2-3 flat plates on the fire side are plenty. Play with spacing between them until your temp is uniform. I have 2 large one. My spacing is 1/4 off the firebox wall and 2 inches between plates. Temp stays within 5-10 degrees from left to right.

Comment

-

Awesome build. Lots of info in there. I need alot more info on reverse flow I think that's the route I wanna go.Originally posted by hellbndr23 View Posthttp://discussions.texasbowhunter.co...ghlight=Smoker

This is mine. If you have any questions on it let me know.

Comment

-

There tons of info out there. Essentially run a piece of angle iron, V up and angled to a drain from on end to the other. Plate from angle to the sides of the pipe. Have it touch the fire box wall and be a few inches away from the far wall. Put smoke stack on firebox end at or below grate level. Forces smoke and heat to travel full length of pit below plates, then again the other direction over ur meat.

Comment

-

You need to figure out what size pipe your gonna go with, and how long you want it. Then use feldons pit calculator to size your firebox, & openings. This will get you a pretty good baseline starting point.

Next, spend some time searching build threads on the forums, and figure put how you want to detail it out. Start a build thread here, and when you get hung up on something, we will help you figure it out.

Comment

-

Originally posted by Palmetto View PostYou need to figure out what size pipe your gonna go with, and how long you want it. Then use feldons pit calculator to size your firebox, & openings. This will get you a pretty good baseline starting point.

Next, spend some time searching build threads on the forums, and figure put how you want to detail it out. Start a build thread here, and when you get hung up on something, we will help you figure it out.

Yes definitely do the math. Feldons has it figured out. Last thing you want is a nice looking pit that won't make heat.

Comment

-

For ours at the lease we built a four sided box with the baffle inside it. Then welded it in the fire box over the opening to the cooking chamber. The baffle has a handle that goes through the side of the fire box to rotate and control the baffle. Wish I had a picture to show you.Originally posted by horns07 View PostThanks. So the the tuning plate on reverse flow is welded in solid correct? The one thing I'm stuck on is how to build a baffle between fire box and the cook chamber. Can someone help me there.

Comment

-

I have been working on this pit for over a year I did take about 5 months off and didnt do much to it. I still have a lot to work on but it's getting closer :D Im going to post from the start. I will be copying from another site and posting it here. April 2nd Well I guess this will be the...

I have been working on this pit for over a year I did take about 5 months off and didnt do much to it. I still have a lot to work on but it's getting closer :D Im going to post from the start. I will be copying from another site and posting it here. April 2nd Well I guess this will be the...

This guy has a good build.

Comment

Comment