In the next couple of years I want to be set up to build my own custom rifles. I am needing some insight on where to look for knowledge as far as running a lathe goes. I am looking at a grizzly gunsmith lathe. Give me some opinions on lathes, tools I will need for the lathe etc. This isn't anything I'm going to start tomorrow, I just want to get things ready to start buying my tools a little at a time. Thanks

Announcement

Collapse

No announcement yet.

Building Custom Rifles

Collapse

X

-

Best to find someone who can show you. I had to learn by trial and error with lots of errors. YouTube is a valuable resource. Start now watching people on there threading, chambering, truing, etc. By the time you watch a couple hundred, you will have an idea what equipment you would like to have that you can afford. When you start out, work on projects that don't cost a lot if messed up. I have broken and bent a few bits along the way. I always leave at least 1" leeway when threading barrels in case I mess up and have to go shorter. Last year, for fun, I built a 6.8 SPC rifle on a Savage short action using a plain barrel blank--threaded, tapered, chambered,etc. Threaded muzzle for my Form 1 suppressor I made a couple of years ago. I have an old Taiwan 12x36 lathe with a 1 1/2" throughbore. It is a good size for gun work. Can't afford a milling machine yet.

-

Before tinkering with building rifles I suggest to learn the basics of machining. It's not rocket science but it does take some skills. Some things/skills can be learned watching YouTube and the like but there is no better way than "hands on" for practical machining. Some trade or junior colleges in your area might have classes you can take or you might try local shops and ask about be an apprentice to learn.

Old American iron is still out there to be had but you have to be patient in looking. That's my first choice. While the imports are often frowned upon they with get the job done too. I have both and get by.

You will find the tools associated with mills/lathes will be the expensive part. Indexable carbide tool are not cheap, neither are good quality measuring devices such as mics, calipers and dial indicators.

You can take aluminum which for the most part is easy to work with and start making chips to learn with. You will also find that machining different metals that they each have a preference with certain type tooling such as tool steel or carbide , coated and uncoated etc. Again this type of thing just comes with time and getting to know your machine and your capabilities.

Comment

-

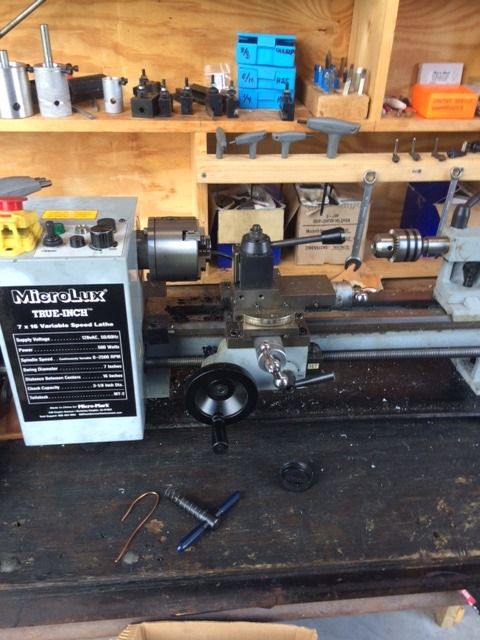

I've always wanted a lathe so about a year ago I bought one. I started with a mini lathe just to keep from killing myself or losing body parts right off the bat.

After progressing with the mini lathe I went bigger a couple of weeks ago. My new used lathe is a 14-40 with a 1.5 spindle.

I have the machine to do barrel work just not the knowledge. I don't know if I will ever decide to go that far but wanted a machine big enough just in case I did. I'm not sure it it's worthwhile to get set up unless you plan on doing it for profit. Plan on spending as much or more on tooling and measuring instruments.

I mainly build reloading tools for myself. You'll never look at a piece of scrap metal again without thinking what can be made out of it.

Comment

Comment