dang tubby! your work is amazing!

Announcement

Collapse

No announcement yet.

Show off your leather

Collapse

X

-

I've noticed things looking better myself, and I'm proud. Thanks for the kind words!Originally posted by Allaround View PostFirst off let me just say......look at the pictures of the first few projects that you did.....now compare them to these latest projects.....now pat your self on the back.

You've come a long ways in a short time and have become quite the talent.

I burnish the areas that will be difficult to get too, such as the entrance hole of a sheath or holster or the belt loop, once the project is assembled. After assembly and after I've trimmed the seam then I'll burnish it. It is also done after all stamping and dyeing but prior to sealing or waxing.

For tools I just use my edge slicker.

I wet the edge down with a moist sponge and then rub some Fiebings saddle soap, in bar form, on the edge to help lube it up. The edges seem to slick up better when lubed.

Sometime I use Edge-Kote if it's going to be a shiny finished project but if I'm looking for a more rugged look then I'll just use another dye of a different, usually darker color.

I've been doing the "hard to get to" areas prior to stitching, learned that the hard way. Where I've been "messing up", is burnishing AFTER sealing but prior to waxing. I'll try it post dyeing, pre-sealing.

Where I've been "messing up", is burnishing AFTER sealing but prior to waxing. I'll try it post dyeing, pre-sealing.

I'm using some cocobola slickers for my Dremel, the Tandy wood slicker, horn slicker and a custom made Cocobola slicker (smaller than the Tandy but same shape) with an awl on the small end. I'll use the Dremel first then finish it out with the hand slickers.

Thanks! I've only been doing this not even 2 years, I'm still learning. Geoff (Allaround) is teaching me a lot.Originally posted by Tylerbost33 View Postdang tubby! your work is amazing!

Where did you get that one made? I like that!Originally posted by Allaround View PostThis is the slicker that I use Tubby.

[ATTACH]361801[/ATTACH]

Comment

-

It's not custom. It's a cocabola that I got from Hidecrafters years ago. It's real handy. I knew a guy up in Oklahoma that made one very similar to this one only made out of mesquite.Originally posted by Tubby View PostI've noticed things looking better myself, and I'm proud. Thanks for the kind words!

I've been doing the "hard to get to" areas prior to stitching, learned that the hard way. Where I've been "messing up", is burnishing AFTER sealing but prior to waxing. I'll try it post dyeing, pre-sealing.

Where I've been "messing up", is burnishing AFTER sealing but prior to waxing. I'll try it post dyeing, pre-sealing.

I'm using some cocobola slickers for my Dremel, the Tandy wood slicker, horn slicker and a custom made Cocobola slicker (smaller than the Tandy but same shape) with an awl on the small end. I'll use the Dremel first then finish it out with the hand slickers.

Thanks! I've only been doing this not even 2 years, I'm still learning. Geoff (Allaround) is teaching me a lot.

Where did you get that one made? I like that!

Comment

-

Oh, meant to tell you... Remember you giving me advice on glue, Duall 88? Well, I ordered some from Hidecrafters, with a few tools (lifters & stamps). Over a week later, I finally got a return email saying they no longer carry those products. Got a refund the following day.

Just a head's up as their website is not up to date. I imagine it'll be a matter of time before they close shop...

Comment

-

Yeah.... That's a shame. They used to be the best and I knew everyone there. I hate to see them end this way.Originally posted by Tubby View PostOh, meant to tell you... Remember you giving me advice on glue, Duall 88? Well, I ordered some from Hidecrafters, with a few tools (lifters & stamps). Over a week later, I finally got a return email saying they no longer carry those products. Got a refund the following day.

Just a head's up as their website is not up to date. I imagine it'll be a matter of time before they close shop...

With them shutting down and Tandy's not carrying a lot of the products I like, I'm doing a lot more mail ordering these days.

Comment

-

Mail order is all I'm limited to unless I take a road trip. And for no longer than I've been doing this, I can already see Tandy trying to carry "their own" line of products...Originally posted by Allaround View PostYeah.... That's a shame. They used to be the best and I knew everyone there. I hate to see them end this way.

With them shutting down and Tandy's not carrying a lot of the products I like, I'm doing a lot more mail ordering these days.

BTW, how are you set up on weekends? You around the leather shop then?

Comment

-

Usually unless I'm shooting a 3D or hunting. Why what's up?Originally posted by Tubby View PostMail order is all I'm limited to unless I take a road trip. And for no longer than I've been doing this, I can already see Tandy trying to carry "their own" line of products...

BTW, how are you set up on weekends? You around the leather shop then?

Comment

-

Well, I had an eventful evening. Seems that my sewing machine wanted to get the bobbin thread bound up a couple of times. I tweaked, adjusted, re-spooled, pulled my hair out... and then IT happened. The bobbin thread locked and I was in mid stitch and brought the handle back and "pop"... not good...

This was the gear for the needle shaft...

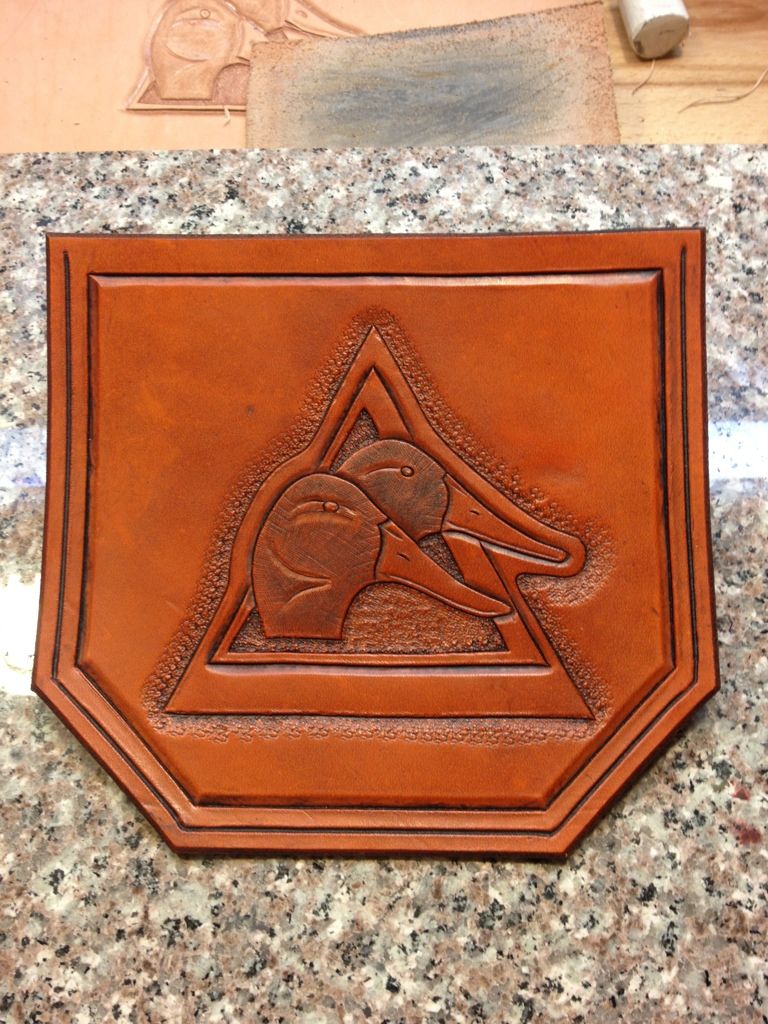

Anyway, I got some staining/coloring done on the Delta Waterfowl Shotshell bags. The one that's painted with Cova-Color, is just a practice piece. I know that once I stain it, it'll look different, and the white will have to be repainted. "If" it comes out decent after staining (and repainting the white), I may go ahead and put it together.

Original Delta Waterfowl Decal

Stained only with Saddle Tan then buffed

Painted with Cova Color. I had a couple of middle school art class flashbacks when I was mixing the colors to get it right.

Comment

-

I don't guess I'd ever noticed this but this is what I observed. I should have taken pictures...

Tippmann Boss machine....

During the "down stitch" (needle entering the leather), the thread that goes thru the needle hole and thru the needle foot would have excess thread hanging out in a loop to the side of the needle. This loop would press against the inside edge of the presser foot. It would make the stitch ok (visually from that side of the leather) and take up the excess slack when progressing with the stitch. Once that stitch was made and advanced to make the next one, the loop would form again on the down stroke.

I referenced the Tippmann manual and the troubleshooting section. I adjusted the primary and secondary tension adjusters. I began by backing them all the way out, bringing the nut until it touches the tension spring. 2 full turns on the secondary tensioner, and 1 1/2 - 2 full turns on the primary tensioner. I checked the thread takeup arm to make sure it was holding tight. With the tension adjusters, making them tighter to remove this excess string, it would be WAY too tight to stitch.

I don't guess I'd ever noticed the loop before but once I saw the thread getting bound up on the back side (from the bobbin), I took special notice to how the machine was stitching.

Anyone noticed this loop of thread on a Boss machine?

Comment

-

Couple of questions. I'm having a hard time making my basketweave look consistent. First of all, out of the many different basketweave stamps available, are some easier/harder to use than others? I watched a Tandy video on the technique but I'm still not where I want to be, both in consistent depth and lining them up right. Any tips? Just more practice?

Comment

Comment